Tooling

Mold Making/Tooling

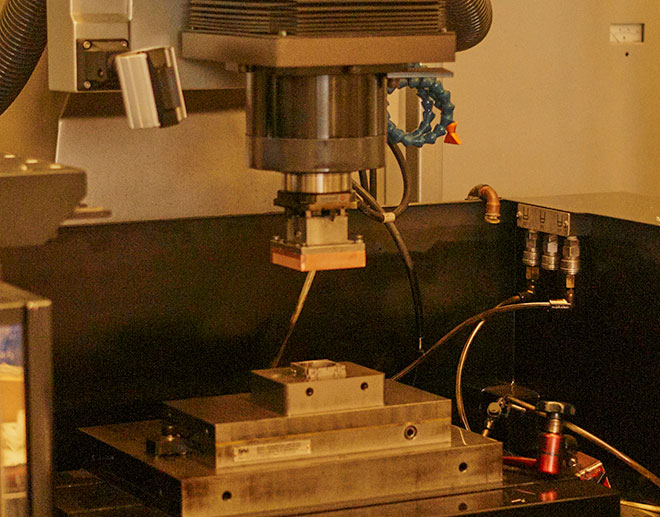

Sentera Plastics offers its customers access to fully integrated molding services. Our plastic injection molding and tooling is highly customizable, enabling us to create injection molded parts that perfectly match your design specifications. Plastic injection tooling includes shaping and producing the metal components of a mold that will give a product its final shape. Tooling requires careful planning so that each casting cavity and core box of a mold is perfectly designed to manufacture products that will meet required specifications. We utilize several different digital prototyping tools including